French businesses use two types of water cooler : fountains with carboys and mains water coolers. The latter is the specialty of Mistral Constructeur, your water cooler manufacturer. Directly connected to the water network, the advantage of this type of water cooler lies in the fact that it requires no logistics to ensure the water supply (from delivery of the carboys to their removal and recycling). In addition to reducing the carbon footprint, water coolers also enable their users to enjoy clear, pure and excellent water. In this article, we’d like to reveal all the secrets and operating stages of the networked water coolers we offer our customers.

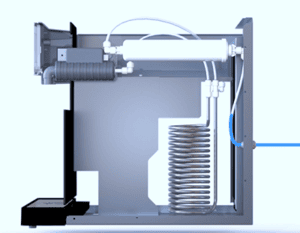

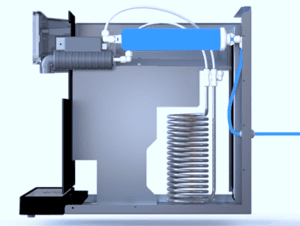

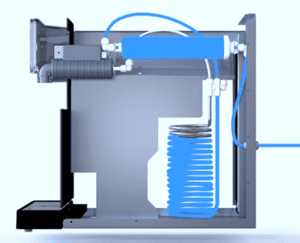

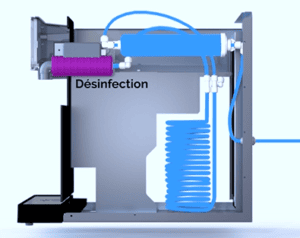

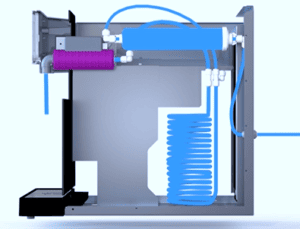

First, water from the public network enters the fountain circuit. The filtration system then filters out any impurities present in the water. Although mains water undergoes several stages of filtration upstream, additional filtration is necessary to ensure that no impurities, however small, remain. The next stage in the water cycle is the cooling coil. It is at this stage that the water is cooled before being distributed to users. Before finally being distributed, the water undergoes a final stage : UV disinfection, for fountain models equipped with UV disinfection and according to the demands and needs of the purchaser.

All these stages may differ according to the options available on the water cooler. Indeed, the UV disinfection system is not systematically installed on the fountains we manufacture, assemble and supply. On the other hand, equipment for producing sparkling or hot water can also be part of the water cooler circuit.

Depending on your needs, we adapt our equipment to provide clear, pure water for your customers and users.